Contact sales

Looking for packaging solutions? Learn more or request a free quote.

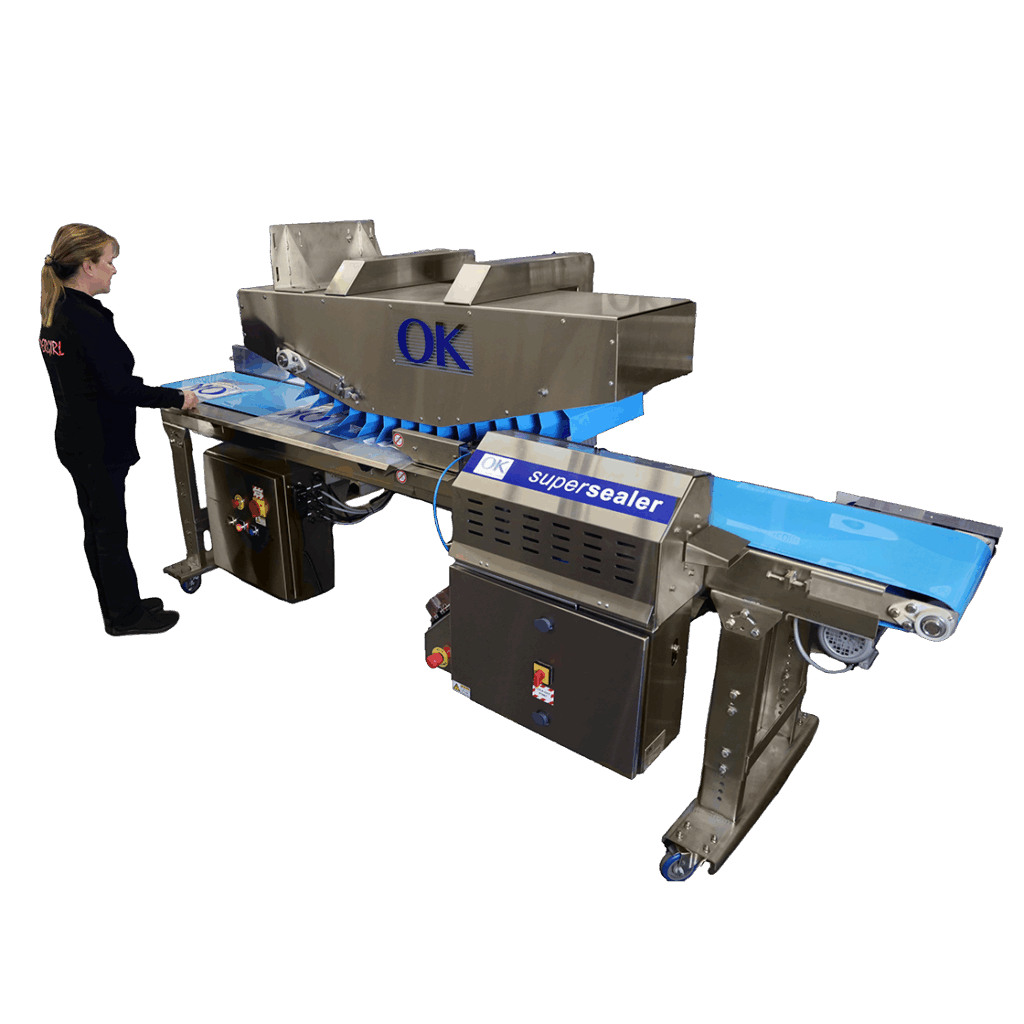

T-PAK 550 Washdown Bag Compression

The T-PAK 550 WD System is equipped with a flat conveyor and a blue FDA Cleat compression belt. It's available in either IP65 or IP69K rated version. The bag with the product comes down the conveyor belt and under the cleat compression belt, which takes the air out of the bag without harming the product. The bag then enters a Supersealer hot air or band sealer to get the “Perfect Seal”. This platform makes this an unchallenged heat-sealing system for many applications superior in performance and speed with low maintenance costs.

Our washdown bag sealers are ideal solutions for clean-room packaging environments and packagers that require strict cleaning standards. Our stainless steel and IP65 rated bag sealers are trusted worldwide by bakery, seafood, chicken, meat, produce, agricultural, and other manufacturers that require frequent cleaning of their packaging equipment.

All the sealers are available in right to left or left to right configurations.

It runs on 110 volt or 220 volt, it can be plugged into any wall socket.

It is CE marked.

Features | Benefits |

Supersealer Bag Sealer: Supersealer Bag Sealer: |  Superior performance for many years. Superior performance for many years. |

Washdown IP65 or IP69K: Washdown IP65 or IP69K: |  Allows for frequent cleaning requirements to be met. Allows for frequent cleaning requirements to be met. |

Finish: Finish: |  Stainless Steel standard, Powder coating optional. Stainless Steel standard, Powder coating optional. |

Full Compression Belt Full Compression Belt |  Removes excess air from the bags. Removes excess air from the bags. |

Automatic Bag Presentation Automatic Bag Presentation |  Optimum seal quality and aesthetics. Optimum seal quality and aesthetics. |

Touch Panel Monitor: Touch Panel Monitor: |  Operators, Managers, QC personnel can always see all variables of the machine at all times, both set and actual. Operators, Managers, QC personnel can always see all variables of the machine at all times, both set and actual. |

Modular Design with Individual Frames on Wheels. Modular Design with Individual Frames on Wheels. |  Mobility and easy access for maintenance. Mobility and easy access for maintenance. |

Machine Handling: Machine Handling: |  Right to left, or left to right. Right to left, or left to right. |

Easy Lift Cover: Easy Lift Cover: |  No tool required for band change with easy access. No tool required for band change with easy access. |

TECHNICAL SPECIFICATIONS | |

| Bag Size Range: | All Bag Sizes. |

| Speed: | Variable to match Supersealer. |

| Standard Features: | Product placement on the main conveyor is aided by a back guide and bag top guide. |

| Machine Handing: | Right to Left or Left to Right. |

| Electric Requirements: | 110 VAC, 1 PH, 60 Hz, 10 Amp 220 VAC, 1 PH, 50 Hz, 7 Amp CE Marked. |

| Pneumatic: | Not required for standard configuration. Required for optional jet flow trim remover. |

| Belt Length: | 10′ or 3 meters. Other sizes on request. |

| Belt Width: | 16″/406mm or 18″/457mm. Other sizes on request. |

| PLC Control: | Touch Panel. |

Add-on Options

- Bag Top Trimmers

- Trim Removers 3" (76mm) or 5" (127mm)

- Automatic Infeed

- Bag Coders and Printers

- Conveyors

- Bag Fillers and Bag Loaders